GAF Commercial Roofing Products

Quality You Can Trust

From North America’s Largest

Roofing Manufacturer

With GAF being the largest North American roofing manufacturer since 1886, the company has produced both residential and commercial roofing products that are not only energy-smart and sustainable but are specifically designed to meet the ever-changing technological needs of commercial clients.

In addition, numerous guarantees on GAF commercial roofing products, savings events, and sustainability programs have also made the use of GAF products an asset to commercial consumers.

GAF’s goals and company principles have always been to help commercial contractors build and maintain businesses that incorporate steep-slope and commercial roofing systems, as well as roof restoration, repair and maintenance, and new and innovative roofing systems.

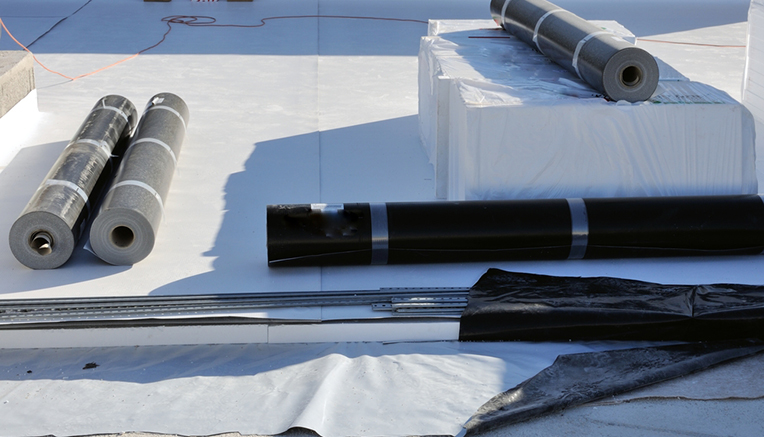

The following product categories and overviews give commercial contractors and others an idea of what GAF currently offers in the way of single-ply roofing, liquid-applied roofing, modified bitumen roofing and built-up roofing.

GAF Single-Ply Roofing

Single-Ply commercial roofing products bring flexibility through membrane sheets that are resistant to the sun’s harmful ultraviolet (UV) rays, and they are available in material choices and thicknesses. The membrane is easily installed through the layering of a single-ply sheet that can be attached with adhesives, fasteners or through self-adhesion. Single-ply roofing is cost effective and includes both TPO (Thermoplastic Polyolefin) and PVC (polyvinyl chloride) products.

TPO and PVC

Both TPO and PVC are cost effective, durable, low maintenance and are highly reflective.

TPO (Thermoplastic Polyolefin)

Thermoplastic Polyolefin, or TPO, is suitable for use with all kinds of single-ply applications, and it is guaranteed for up to 30 years. TPO weathers extremely well, is flexible and is resistant to tears and breaks.

Searching For GAF Commercial Roofing Companies Near Me?

Find GAF Commercial Roofing Contractors Near Me

It is available in varying forms for commercial roofing needs, which include the following products for roof surfaces:

TPO Surface Types

- Smooth – 45, 60 and 80-mil membrane

- Fleece-back – 45, 60 and 80-mil membrane

- Extreme Fleece-Back – 50, 60 and 70-mil membrane

- Freedom – HW Membrane – Membrane with RapidSeam Technology

TPO Products

- TPO – Everguard Extreme – is ranked as one of the best applications for use with any commercial roofing project that incorporates usages for even high heat and solar applications.

- TPO – EverGuard, EverGuard FB Ultra, which is designed for ultimate performance with commercial roofing projects and is also for use with extreme heat and solar applications.

- Self-Adhering TPO – EverGuard Freedom is designed for a fast, easy and limited odor application when a membrane needs to be applied quickly.

PVC (Polyvinyl Chloride)

Polyvinyl Chloride (PVC) is comparable to TPO in its reflective abilities and is viewed as the original or fundamental weldable roof single-ply sheeting. Though its plastic content has been questioned due to possible deterioration of components within it, improvements have been made over time, and PVC still remains a practical, reliable and versatile alternative to TPO. Its use is guaranteed for up to 25 years.

PVC is resistant to chemicals and it is not impaired or weakened by grease and oils, which makes it a membrane that is suitable for buildings and restaurants that utilize grease traps on their roofs. PVC is also a bit more flexible than TPO and also welds membranes quite easily.

PVC Surface Types

- Smooth – EverGuard PVC – available in 50, 60 and 80-mil membrane

- Fleece-back – EverGuard PVC – available in 50, 60 and 80-mil membrane

- PVC XK – EverGuard PVC XK – available in 50, 60 and 80-mil membrane

- PVC XK Fleece-Back – available in 60 and 80-mil fleeceback membrane

PVC Products

EverGuard PVC 50-mil Membrane

EverGuard’s PVC is flexible, resistant to UV rays, as well as chemicals, ozone, punctures and tears. Its seams are heat-welded and the membrane is a reflective white in color for energy savings. The membrane is easy to install and repair, and guarantees are available for up to 15 years.

EverGuard Fleece-Back Single-Ply PVC Roofing Membrane

Everguard’s PVC Fleece-Back Membrane is a polyester fleece that is applied in the factory and gives added protection to the roof membrane. Slip sheets are unnecessary when covering over any number of roofs. The membrane also provides resistance to punctures, particularly hailstones. Even more benefits are derived when using GAF’s two-part roofing adhesive. Guarantees are available up to 20 years and other benefits include seams that are heat-welded, along with excellent reflectivity and ease of installation and repair.

EverGuard PVC XK

EverGuard’s PVC XK has enhanced flexibility and expanded resistance to the sun’s harmful UV rays that generate energy savings. Resistance is also heightened against chemicals, ozone, punctures and tears. Seams are heat-welded and the membrane’s white color improves reflectivity. It is simple to repair and maintain and installation happens in three easy steps. Guarantees are available for up to 12 years.

PVC XK Fleece-Back

PVC XK Fleece-Back is a polyester membrane that contains a protective polyester fleece backing that is applied from the factory. Like other GAF fleeced-backed membranes, no slip sheet is required when covering over old surfaces. Puncture resistance is greatly boosted, particularly for regions that experience hailstone damage. KEE (Ketone Ethylene Ester) a polymer with stretching and reshaping properties, provides exceptional weathering features. Fleece-back installation is highly efficient when combined with GAF’s two-part adhesive. Other benefits include seams that are heat-welded, simplified installation and repair, plus superior reflectivity. Guarantees are available for up to 15 years.

GAF Liquid-Applied Roofing

Liquid-Applied roofing is fabricated from a number of different materials that come together to maintain the stability of a building, while they provide exceptional protection from outside elements. Liquid applications are reliable and are easily applied without dealing with added insulation or tear-offs.

Different Coating Types

Liquid components for commercial roofing consist of different types of coatings, such as:

PMMA

United Coatings PMMA Catalyst is combined with PGMA Resin that is available in summer or winter grades. When combined with flashing resin, area substrates like built-up roofing systems (BUR) and SBS (styrene-butadiene-styrene) modified bitumens can be reinforced with coatings to cover areas of cracks, joints, splits and seams.

Acrylic

United Coatings has created a large line of acrylic water based and acrylic polymer coatings that are Energy Star rated and protective of insulation as well as deterioration from sun exposure, weathering and aging. These coatings offer coverage for all types of weather conditions, including ice, snow and sand. Its dense, tough and non-penetrable surface finish is stable under almost any condition.

PVDF

United Coating’s Kymax Coating is a barrier product that helps contain soft plastics and other related substances from migrating. It prevents asphalt seepage, weathering and reflective issues that involve mildew, mold, algae and other airborne particles. It is a highly flexible yet tough substance that has an enamel-like finish, which is resistant to wear, dirt, oil, weather excesses and exterior organisms.

Silicone

United Coatings Unisil HS Roof Coating is a tight surface finish that provides weatherproofing, resistance to ultraviolet light (UV rays) and protection from mold, mildew, algae and other organisms. It is a pure silicone polymer that is also resistant to fire and can withstand extremes with hot and cold temperatures.

SEBS

Topcoat Surface Seal SB is an Energy Star rated sprayable rubber sealant that sets up and forms a rubber membrane that is seamless. It is extremely reflective and flexible and it provides added protection to a roof, plus it can easily deal with temperature extremes that can bring on expansion and contraction.

United Coatings’ Surface Seal SB Roof Coating is another Energy Star rated product that is solvent based and is a sprayable rubber coating. It sets up quickly and forms a rubber membrane that is seamless. Not only is it extremely reflective, but it provides added protection and adjusts to temperature extremes, and the expansion and contraction that occurs with roof systems. It is an ideal substance for use with wood, metal, concrete, built-up roofs (BUR), modified bitumen and EPDM, which is synthetic rubber used in low slope buildings.

Urethane

Elastuff 101 Base Roof Coating is used with Elastuff 103 Roof Coating to create a covering that provides flexible and malleable strength coupled with weatherproofing, hardness, durability and resistance to chemicals, mildew and dirt. The substance builds a protective membrane that covers new or older roof underlayers (substrates), such as asphalt, metal, concrete, and polyurethane foam. It can also be used in both vertical and horizontal applications that require a membrane that is tough and resistant to abrasions and chemicals.

GAF Modified Bitumen Roofing

GAF’s modified bitumen roofing membranes are strong yet flexible, resistant to impact and are compatible with a number of roofing systems. The available systems offer base and cap sheets that can applied through hot asphalt, torch application or a cold process application.

Types Of SBS Membranes

- Cap Sheets (Mop & Cold)

- Cap Sheets (Heat-Weld)

- Base/Interply (Mop & Cold)

- Base/Interply (Heat-Weld)

- Base/Ply (Self-Adhering)

- Cap Sheet (Self-Adhering)

- Base (Mechanically)

- Base/Interply

- Tri-Ply Cap Sheet

GAF Built-Up Roofing

Built-up roofing is a multi-ply membrane that contains layers or plies of varying materials (felts, fabrics, mats) that have alternate layers of bitumen applied between them. Most built-up roof membranes contain a mineral or bitumen surface, the coating that is an applied liquid, or a cap sheet that has a granule surface.

One product, GAFGLAS BUR (built-up roofing) decreases the cost of installation while it is able to deal with difficult roof applications.

Types Of GAFGLAS BUR Roofing

Base Sheet – an infused, saturated, or coated felt that is used as the first ply in various multi-ply, modified bitumen or built-up roof membranes.

Cap Sheet – a sheet that has a granular coating that is used as the top ply for particular modified bitumen or built-up roof membranes as well as flashing.

Ply or Ply Sheet – an actual ply sheet or a layer that strengthens or reinforces a roof system or roof membrane.

Tri-Ply BUR

Tri-Ply Built-up roofing is an asphalt altered membrane that can be cold or torch applied.

Types Of Tri-Ply BUR

- Tri-Ply Base Sheet

- Tri-Ply Cap Sheet

- Tri-Ply Ply Sheet

GAF commercial roofing products and the numerous roofing materials they manufacture give commercial roofers a wide variety of options for almost any commercial project, large or small. If you have questions concerning any of the systems or products mentioned here, feel free to complete the online contact form and a commercial specialist will get back to you with the answers you need to start or finish your building project.